Last week I had an interview with Jasper at the workshop from the Hanze Racing Division (HARD). Jasper is a first-year student of the three-year Mechanical Engineering Bachelor’s Program who joined the team earlier this year. He joined to take on an additional challenge during his regular education program.

Jasper and Mark discussing in HARD’s workshop

‘IN A NORMAL ENVIRONMENT AT SCHOOL YOU GET TO WORK WITH 15 COMPONENTS, HERE YOU CAN WORK WITH AT LEAST A THOUSAND!’

Jasper took an interest in working on a racecar through his studies in Delft, where they have a Formula Student team as well. By then, Jasper didn’t have enough time to join the team, but since he started studying in Groningen he found the time and decided to join HARD. What Jasper likes most is the hands-on practice while working on race cars. ‘In a normal environment at school you get to work with fifteen components, here you can work with at least a thousand!’ Besides that, he has fun working in a competitive environment as he wants in order to build the best possible race car.

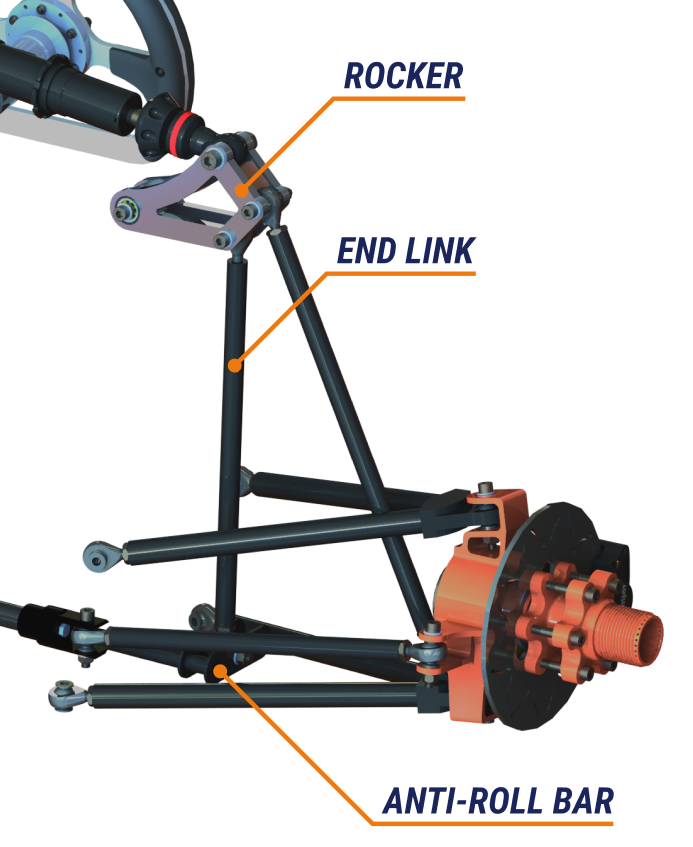

FRONT-WHEEL SUSPENSION SYSTEM

Jasper is currently working on the sway bars and end links for the car’s front suspension. The sway bars ensure that the vehicle’s roll is controlled during cornering, by transferring load from one wheel to the other. As shown in the picture, the rockers rotate during suspension travel, which moves the end links, actuating the sway bar. Jasper made sure to set up the end links in the correct orientation, to prevent components from binding during suspension travel. With our computer software, we were able to test the placement and actuation of the components in advance, allowing us to install them correctly on the car on the first try.

3D render of the front-wheel suspension system

Thanks to this experience, Jasper can learn competencies that his program doesn’t teach, and perfect the skills his program does offer. In this way, HARD helps him to further develop his mechanical engineering expertise by creating a competitive but friendly environment while having the goal of building together a racecar.

SOCIAL CONTACT DURING COVID-19

In the current COVID-19 time, it is still nice to have social contacts in a safe environment. The team is very excited about building the new car, even though the workshop is working on a maximum capacity of 5 people. Due to this restriction, a lot of online communication is being used which works reasonably well. Efficient planning is used to ensure the workshop is never over the safe capacity while it encourages members to continue with the racecar’s development.